Holcim ViroDecs®

Ready-mix concrete embodied carbon emissions reductions revealed

Examples of the magnitude of emission reductions offered by Holcim’s ViroDecs® range of ready-mix have been revealed at a major industry event.

The annual Infrastructure Sustainability Council of Australia (ISCA) Conference recently hosted an audience of more than 350 of the nation’s leading sustainability professionals in Melbourne. ISCA is the peak body for advancing sustainability in Australia’s construction industry.

During the conference’s Innovations Workshop, Holcim presented additional Life Cycle Assessment modelling undertaken as part of the ViroDecs® Environmental Product Declaration registration, comparing the cradle-to-gate greenhouse gas (GHG) emissions of the ViroDecs® product range to equivalent Australian-average data for ready-mix concrete.

Highlighting the potential benefits of the lower carbon concrete, Holcim revealed that using ViroDecs® on a hypothetical 500,000m3 large scale infrastructure project instead of the equivalent normal-class concrete from an average Australian supplier could reduce greenhouse gas emissions by up to 170,000 tonnes of CO2-equivalent - a figure equivalent to removing 32,635 cars from Australian roads1, or powering 24,285 Australian homes with renewable energy sources2, for a year.

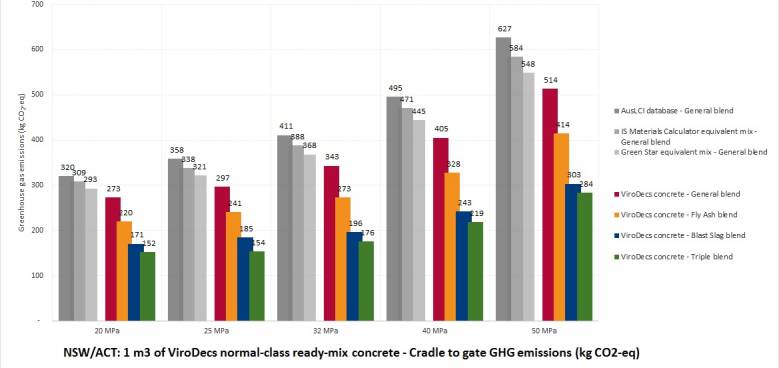

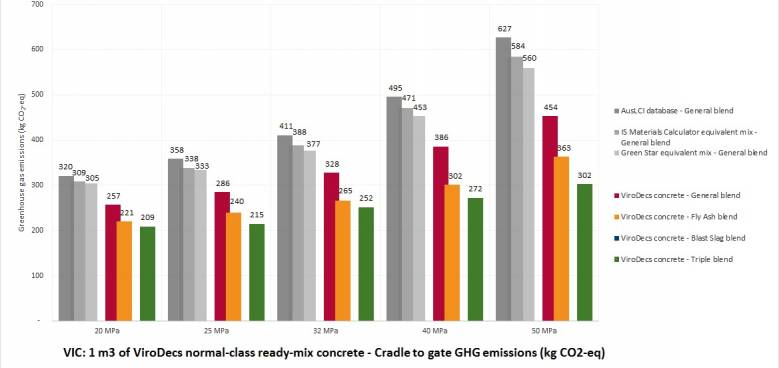

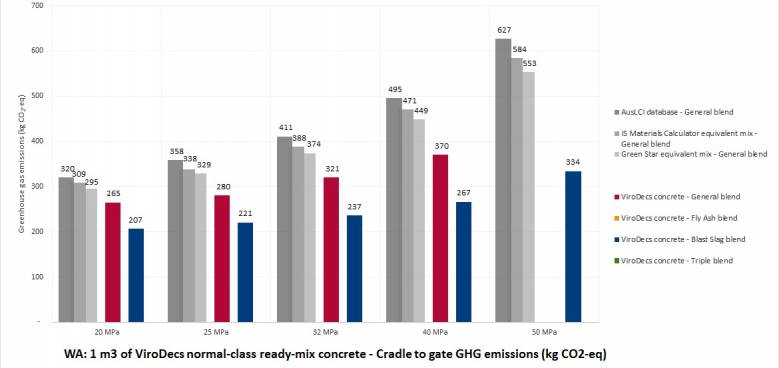

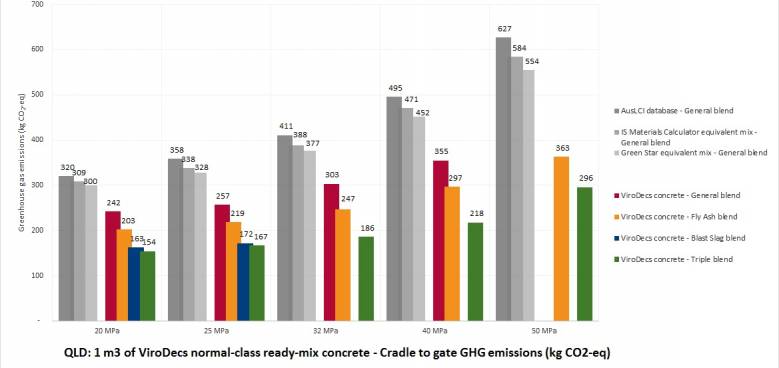

The modelling showed that in comparison to the Australian National Life Cycle Inventory Database’s (AusLCI) general ready-mix concrete:

- ViroDecs® General has up to 28% less CO2-equivalent than the Australian average

- ViroDecs® Fly Ash Blend has up to 42% less CO2-equivalent than the Australian average

- ViroDecs® Slag Blend has up to 52% less CO2-equivalent than the Australian average

- ViroDecs® Triple Blend has up to 57% less CO2-equivalent than the Australian average

Holcim’s Sustainability Lead, Evan Smith, said Holcim remains the only concrete manufacturer in Australia that has developed an ISO compliant, third-party verified Environmental Product Declaration (EPD) to quantify the cradle-to-gate environmental impacts of its ready-mix concrete.

“During ISCA’s Innovations Workshop, Holcim also conducted research on the key benefits of ViroDecs® and how lower carbon concrete is currently specified.

“The survey was completed by a range of stakeholders, including those from government, design and construction. And the findings are quite interesting.”

When asked “what are the key benefits of ViroDecs® ready-mix concrete for your company?”, the respondents answered:

- 66%: “Will provide verified, ISO-compliant data on the reductions associated with Holcim ViroDecs® ready-mix concrete (IS rating Mat-1 credit)

- 62%: “Will also help earn more (IS rating points (Mat-2 credit) for a project”

- 57%: “Provides standardised, transparent and certified data on the various impact of ready-mix concrete”; and

- 57%: “ViroDecs® helps us specify or procure a lower carbon ready-mix concrete”.

Survey respondents were also asked how their organisation or project currently specifies concrete with a lower carbon impact. This question revealed:

- 50% specify by supplementary Cementitious Material (SCM) reduction target

- 33% specify by a reduction of cement from defined reference case (e.g. Green Star)

- 6% specify by a reduction in CO2-equivalent using life cycle analysis and Australia industry average data; and

- 11% generally don’t specify

While a majority of the organisations were pursuing a reduction of concrete impacts, their targets varied greatly:

- 1-10% reduction - 5% of companies

- 10-20% reduction - 19% of companies

- 30-40% reduction - 44% of companies

- 40-50% reduction - 19% of companies

- Carbon neutral - 13% of companies

An Australian first

Registered with EPD Australia in August of 2019, the ViroDecs® Environmental Product Declaration is an Australian first for ready-mix concrete.

The ViroDecs® EPD is an ISO compliant, third-party verified life cycle assessment which quantifies the environmental impacts of Holcim’s ready-mix concrete in a standardised format across more than 24 impact categories.

The project collected data from over 3,000 mix designs from across Holcim’s Australian operations, including 190 concrete plants and 46 quarries.

Environmental data collected in the assessment included diesel, energy, water, wastewater, waste and air emissions.

The development and registration was carried out over a period of two years and takes into consideration major issues including global warming, ozone depletion potential and the use of secondary materials.

“EPDs bring credible transparency because they rely on an objective, scientifically accepted methodology and are third-party verified and publicly available,” said Evan.

The Project’s Steering Committee was a multidisciplinary team of 12 Holcim team members, including specialists in environment, sustainability, technical, logistics, operations, sales and marketing.

Normal-class ViroDecs® concrete covers four blends, six states and five different strength grades. These 73 discrete categories are based on the variables that are highly correlated to the environmental impact of concrete and easy to reference by customers.

The EPD registration has enabled customers to clearly undertake sustainable material selections from the Holcim ViroDecs® concrete range, assisting projects to reduce the embodied environmental impacts of their materials and gain credit points in the Green Star and IS schemes.

The Innovations Workshop follows on from the launch of ViroDecs® at the 2018 annual conference of the Infrastructure Sustainability Council of Australia (ISCA) which also generated a high level of interest and praise from customers, government departments and sustainability practitioners.

_____

- Based on 0.401 kg CO2-eq per km of car travel (AusLCI) and an average travel distance 13,400 km per car in FY17/18 (ABS: https://www.abs.gov.au/ausstats/abs@.nsf/mf/9208.0)

- Based on an average greenhouse gas impact of 7 tonnes CO2-eq for an Australian household per year from energy use (http://www.yourhome.gov.au/energy)