Climate Action

At Holcim, we are taking a science-driven approach to becoming a net-zero company. We continue to lead our industry with science-based targets and a clearly defined net-zero roadmap.

Our main climate actions

We were among the first companies worldwide to have our 2030 and 2050 CO2 reduction targets validated by the Science Based Targets initiative (SBTi).

In 2023, as we continue to lead our industry in sustainability, we made strong progress toward these targets for 2030, which are in line with the SBTi’s revised 1.5°C framework.

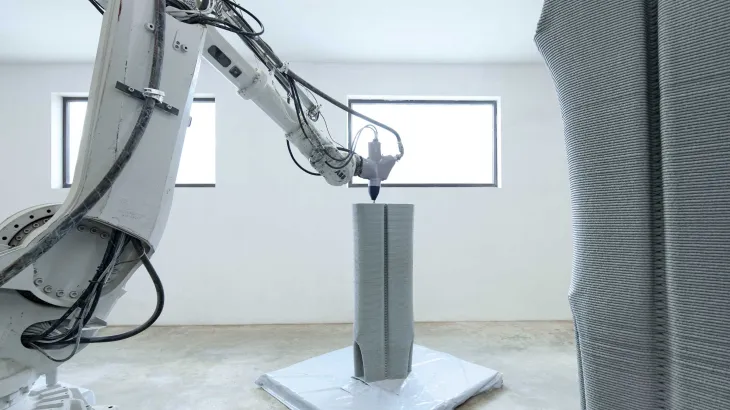

We have set out a clear pathway to net zero. By offering our low-carbon products and by enabling smart design systems, we will support the shift to more carbon-efficient construction.

Products

Solutions

- Reduction in embodied carbon in comparison to Australian Life Cycle Inventory (AusLCI) database value for an ordinary Portland cement ready-mix concrete (i.e. no innovation or use of supplementary cementitious materials). See also: AusLCI concrete background report.